The purpose of the modeling and designing processes is to efficiently and adequately find the path from an IDEA to the PRODUCT. The last step to the final product is the final design.

Within the process of final designing, all relevant data on the product, necessary for its creation are comprehensively defined. The process of final designing also includes creating one or more prototypes, or even pre-production assembly-line prototypes, if necessary.

A prototype is developed for the purpose of testing the product features during its exploitation. Based on the results of such prototype tests, the conclusions are drawn on whether the product structure is over-capacitated or under-capacitated; if the materials chosen are adequate; on tolerances; technological processes of product development, etc.

Subsequently, based on the prototype feedback received, a decision is made on which design would be the optimum one and thus the possibility of making an error and creating an unsynchronized product is avoided.

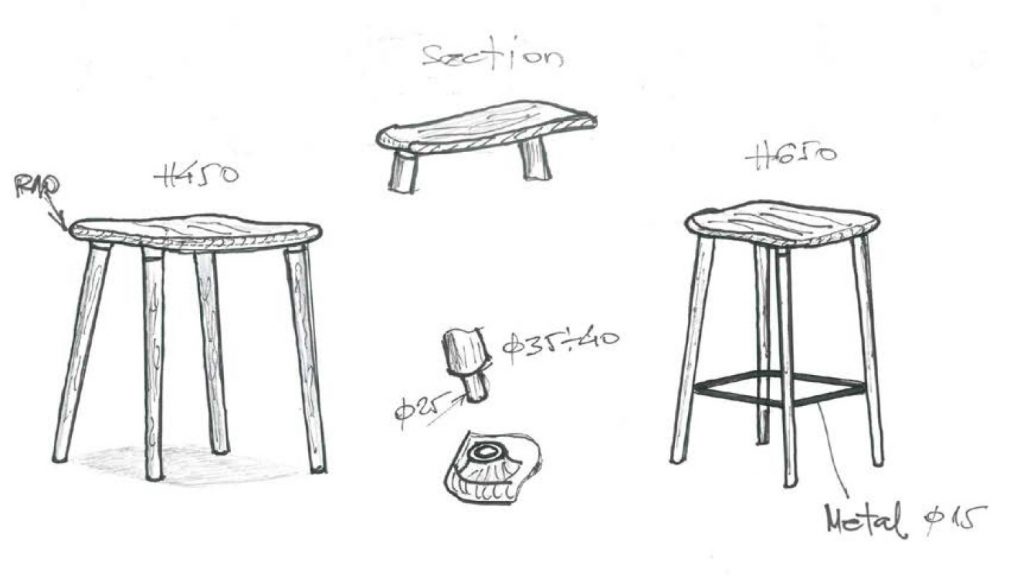

Furniture designing by applying CAD technologies (Simple design)

Negotiated price

The entire designing process is pursued gradually through all stages of designing and product/service development by a highly-educated and qualified team of experts. The designing process is carried out by using SolidWorks 3D-CAD software and includes creating a prototype and its validation.

The actual costs for each user will be agreed depending on the complexity of product and its preparation, the type of wood and tools used. Arteco will honestly endeavor to offer a price that will be attractive to users of this service.

ARTECO Center has a contemporary 5-axis CNC machining center for solid wood board processing. The machining center has been designed to suit difficult machine operations, particularly for solid wood. The characteristic of the center is a sophisticated vertical machining, as well as the utilization of tools and generators on very thick and hard pieces of wood.

The operations of the automatic CAD/CAM (SolidWorks/SolidCAM) programming using 5-axis CNC machine are:

- Creating mathematical model for the workpiece by using CAD software (SolidWorks);

- Transferring mathematical model of the workpiece from CAD to CAM (SolidCAM) program the mathematical model must be in the format readable by the CAM application;

- Tool selection;

- Defining the toolpath and choosing machine-technological parameters;

- Deciding on the method i.e. machining strategy (contour, rough, fine, …)

- Simulation of machining, with the possibility of making corrections in certain sequences (CL file crated) post-processing;

- Sending the program to the 5-axis CNC machine and creating technological documentation;

- Testing the program on the machine and making corrections, if any;

- Making and testing the first piece.